YOON, Jungwon. SMP Prototype Design and Fabrication for Thermo-responsive Façade Elements.

Journal of Facade Design and Engineering, [S.l.], v. 7, n. 1, p. 41-62, nov. 2018.

ISSN 2213-3038.

ABSTRACT

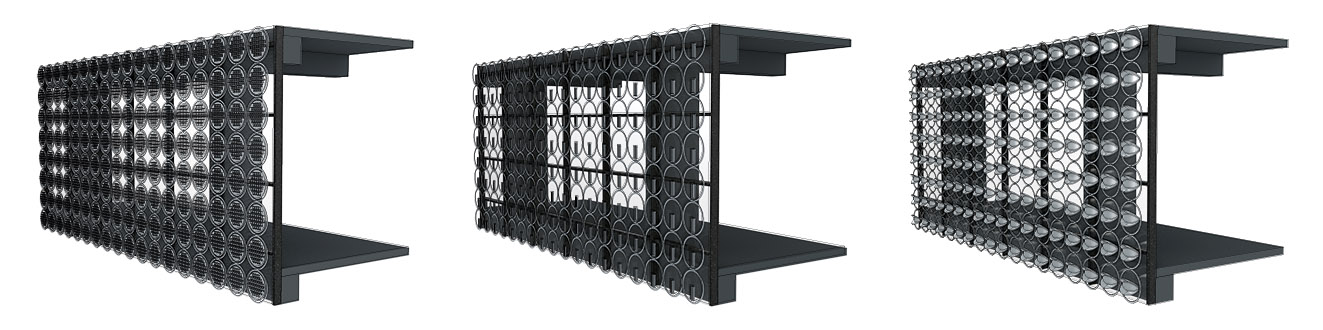

The aim to attain sustainability in the built environment introduced the innovative application of advanced material technologies for low-energy, but aesthetically intriguing, building design strategies. Adaptive and responsive building skins as embedded and intrinsic control systems can be delivered with smart materials, and thus have the potential to minimise the energy consumption of buildings by maximising the natural and passive adjustment of façade components for shading, air-flow, daylight, and view. The dynamic smart material façade, adaptable to changing outdoor environments, is considered to be a holistic design approach that integrates the behavioural performance effects with the appearance and aesthetics of kinetic ability provided by smart materials acting as actuators, by adjusting their properties according to external stimuli. Of the various environmental inputs sensed by, and actuating, active and dynamic building façade systems, this research focuses on temperature as the stimulus to activate a dynamic shading device with the mechanism of opening and closing, specifically considering Seoul’s climate. Among currently available thermo-responsive smart materials, the shape memory polymer (SMP) is investigated as an activator of shading devices to be implemented to adaptive building skin strategies. As the first stage of SMP prototype design and fabrication study toward the thermo-responsive building façade elements, SMP prototypes are proposed in cell types. Among the general thermo-mechanical cycle of thermo-responsive SMP, only programming of the permanent shape via additive manufacturing and recovery at the activation temperature are focused upon in this research. This study proposes a design-to-fabrication workflow integrating computational tools, 3d printing and recalibration of relevant variables in digital design process, G code generation, and manufacturing using commercially available SMP filaments. To verify the 3d printing process, and to demonstrate the shape-changing behaviour of SMP actuators, reproduction of a referenced prototype was conducted, in addition to fabrication experiments of SMP surfaces with various thicknesses and SMP hinges with customised rotating angles. In addition, a base-line prototype combining the static ABS plate and the active SMP hinge is developed to set up the heat test and a digital motion simulation from data of shape changing behaviour acquired from a hands-on model test. After the demonstration of the baseline prototype in design and additive manufacturing process, various SMP prototypes were designed with reference to kinetic prototype researches, but with the consistent 100mm-diameter circular surface, in a scale of 1:3. They were also fabricated with a 3d printer for both open and closed positions to testify to their constructability, and thus to comparatively evaluate the design and fabrication outcomes. Furthermore, after conducting radiation and thermal simulation analysis, shading performance validation is noted for selecting potential prototypes. Lastly, the needs to further develop reversible reiterative shape-changing materials or systems are briefly discussed.

SMP Prototype Design and Fabrication for Thermo-responsive Façade Elements | Journal of Facade Design and Engineering

journals.open.tudelft.nl